We are leaders in presicion machining for the mexican industry, we have highly trained personnel, facilities, equipment, software y measurement tolos of high level.

Oficial Software:

SERMAQ has lathes and CNC machining 3 & 5 axis with the latest tecnology and from the more recognized brands in the industry to offer our clients high precisión standards and the best Surface finishes.

Wire EDM is a manufacture process, in which is used a continuous moving conductor wire, ussually cupper alloy or brass, is fed through the workpiece, submerged in a dielectric fluid, usually deionized wáter. Is used for manufacturing holes and complex shapes from side to side. This process is demanded in stamping industries for cuting parts like punches and dies.

EDM is a non-traditional machining process based on removing material from a part by means of a series of repeated electrical discharges between a electrode and the part to be machined, submerged in a dielectric fluid. This process continues until the electrode´s shape is copied in the part.

SERMAQ has all the conventional machining processes like milling machines, lathes and grinding machines (flat and cilindrical).

Our personnel is trained constantly and have wide experience (more that 10 years) in the industrial machining field.

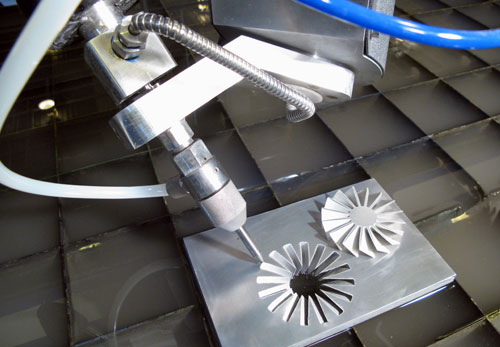

Waterjet Con este proceso de corte no se producen cambios estructurales en los materiales cortados, se pueden ser cortar materiales como el acero al carbón, aluminio, acero Inoxidable, nylamid, platicos diversos, entre otros, su bajo costo y rapidez de corte, hacen a este proceso ideal para piezas que no requieren una tolerancia muy cerrada.

Waterjet is a non-thermal cutting process that doesn´t produce any structural change in cut parts. This method uses only natural sand and wáter to cut almos any material, from soft rubber and plastics to the hardest metals and ceramics. The versatility and ease of operation makes this process ideal for pieces that don´t require small tolerances.

Laser CutLaser cut is a thermal process in which a focused laser beam is used to melt material and separate it. A continuous cut us produced by moving the laser beam or workpiece under CNC control. It has an excellent level of presicion and speed in the process

Oxy-fuel cutting This process uses fuel gases and oxygen to weld and cut metals, respectively. In oxy-fuel cutting, a cutting torch is used to heat metal to kindling temperatura. A source of oxygen is then directed to the metal and the metal burns in that oxygen cutting it.

We have the most common welding processes in industry like MIG&TIG process and laser welding.

Powder coat Powder coating is a dry finishing process that uses finely ground particles of pigment and resin that are electrostatically charged and sprayed onto electrically grounded parts. The charged powder particles adhere to the part and are held there until melted and fused into a uniform coating in a curing oven.

Anodizing Is an electrochemical process that converts the metal Surface, ideally aluminum, into a decorative and resistant finish.This process is acomplished by immersing the aluminum into a acid electrolyte bath and passing electric current through the médium. A cathode is mounted to the inside of the anodizing tank; the aluminum act as a anode, so that oxygen ions are released from the electrolyte to conbime with the aluminum atoms at the Surface of the part being anodized.

Nitriding Nitriding is a heat treating process that diffuses nitrogen into the surface of a metal to create a case-hardened surface. These processes are most commonly used on high-carbon, low-alloy steels.

Black Oxide Black oxide is a conversión coating for ferreous material. It is used to add corrosión resistance, for appearance and to minimize light reflection

Devices used in the production line for dimensional verification.

Read moreLathes and 3 & 5 Axis CNC Machining Centers with the best latest generation technology.

Read moreHERA 2.10.09 bridge type COORD measurement regulated under the ISO / IEC 17025 standard.

Read more2D, 3D designs and process simulation of different devices, equipment and systems.

Read moreWe design from the conception of mechanical and electrical design to commissioning.

Read moreEngineering and planning development for various electrical control circuits.

Read moreProgramming standards of our clients or development according to the requirement.

Read more

With a office in United States we are more close to new business opportunities in North America.

21750 Hardy Oak Blvd. Suite 102 San Antonio TX 78258

+1 (210) 418 2236

+1 (210) 201 5898